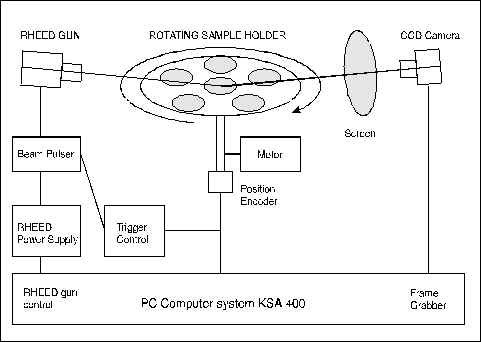

| Sample rotation is needed during the growth process in order to achieve the best uniformity of the deposited layers. This creates a problem for in-situ RHEED analyses because the azimuthal orientation of the sample changes periodically during the rotation. The situation is even more complex when several wafers are grown simultaneously in the same chamber. |  |

RHEED systems from STAIB INSTRUMENTS provide a simple solution: the electron beam is periodically pulsed and the pulses are synchronized with the sample rotation. The pulses correspond to a given sample orientation and are short enough to ensure a well defined azimuthal angle. A CCD camera is also triggered synchronously with the pulse. Pulse lengths are adjustable from milliseconds down to microseconds, depending on the speed of the rotation. The brightness of the pulses, provided by STAIBīs unique RHEED system design, is high enough to allow the acquisition of each single RHEED diagram with a CCD camera.

This simple technique also applies to multi-wafer systems, especially in production lines. In this case, the incident beam is adjusted off axis and explores the side of the rotating sample holder. Each wafer passes sequentially in front of the RHEED gun and a RHEED diagram can be recorded for each wafer. Staib RHEED systems provide the high-precision control of the incident beam angle required for this application.

Our customersī success is our pride!

| The position encoder triggers the RHEED gun and the CCD camera for precise angular positions of the sample. |  |